Fiber laser marking machines have become an essential tool for manufacturing and packaging industries. The technology has opened up a whole new world of possibilities for marking various materials and objects. However, as with any technology, the advancements in marking machines are rapidly evolving. In this article, we will discuss the latest developments and advancements in fiber laser marking machines technology.

Increased Precision

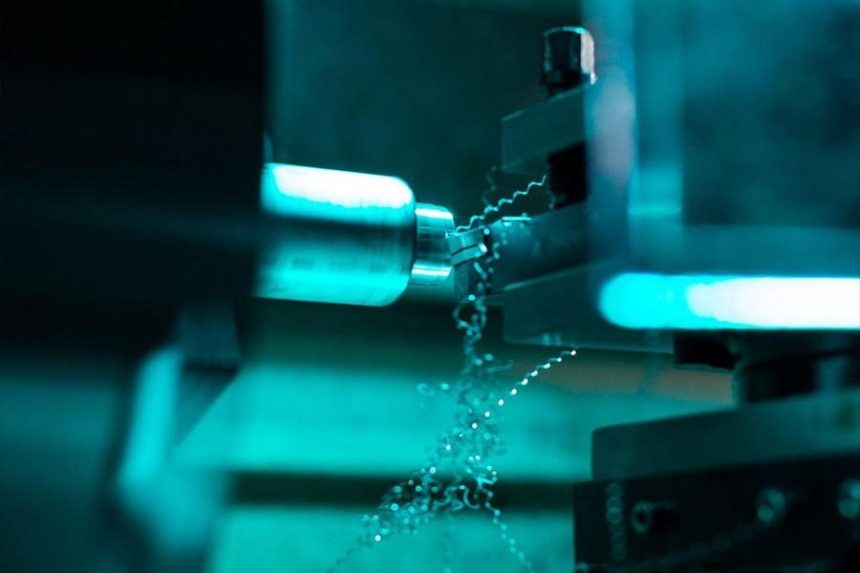

One of the significant advancements in fiber laser marking machines is the increased precision to mark materials with extreme accuracy, even up to a thousandth of an inch. This is a significant improvement from the traditional marking techniques that were often limited by human error and imprecise machinery.

The increased precision is due to the advancements in laser technology, which have led to the development of more powerful and focused lasers. The use of a galvanometer or scanner technology has also improved the precision of the marking. As a result, these advancements have made it easier to engrave and mark intricate designs on materials such as metals, plastics, and ceramics.

Higher Speeds

Another significant advancement in fiber laser marking machines is the increase in speed. The latest machines can mark materials at incredibly high speeds, allowing for faster turnaround times and increased productivity. The speed of marking is due to improvements in laser technology, which can now generate more powerful lasers and focus them with greater accuracy. Additionally, the use of computer-controlled marking has made it easier to mark objects at a faster pace.

These higher speeds are particularly useful for industries that require mass production, such as the automotive and pharmaceutical industries. In these industries, fast turnaround times are essential, and the use of fiber laser marking machines can significantly improve efficiency.

Improved Energy Efficiency

The latest advancements in fiber laser marking machines have also focused on improving energy efficiency. The laser technology used in these machines is continually evolving, and new lasers are being developed that require less energy to operate. This reduction in energy consumption has significant benefits for manufacturers, who can now operate with lower energy costs and a reduced carbon footprint.

In addition to the reduced energy costs, the improved energy efficiency has also led to the development of smaller, more compact fiber laser marking machines. These machines can be easily integrated into existing production lines, saving space and reducing the overall cost of installation.

Integration with Industry 4.0

As manufacturing industries continue to embrace Industry 4.0, the latest developments in fiber laser marking machines are focused on integrating with this new industrial revolution. The latest machines are designed to be easily integrated into Industry 4.0 manufacturing environments, where data is collected and analyzed in real-time to optimize production.

The integration of fiber laser marking machines with Industry 4.0 enables manufacturers to track and trace products from the point of manufacture to the end-user. This level of traceability is essential for ensuring safety and quality control, particularly in the food and pharmaceutical industries.

Smart Marking

Another exciting development in fiber laser marking machines is the emergence of smart marking. Smart marking is a technology that allows for real-time monitoring and adjustment of the marking process. It uses sensors and cameras to monitor the marking process and adjust the laser focus and power to ensure optimal results.

The use of smart marking technology has significant benefits for manufacturers, particularly those in complex industries such as aerospace and medical devices. These industries require precise and consistent marking, and the use of smart marking technology can significantly improve the quality control and efficiency of the marking process.

Conclusion

In conclusion, the future of fiber laser marking machines looks bright, with advancements in precision, speed, energy efficiency, integration with Industry 4.0, and smart marking technology. These developments are significant for manufacturers, as they provide increased efficiency, reduced energy costs, and improved quality control.

As the technology continues to evolve, we can expect even more exciting developments in fiber laser marking machines. The possibilities are endless, and the potential for this technology to revolutionize the manufacturing industry is significant.